Aggregate : Its Types And Uses

Aggregates are a coarse, particulate, rock-like material made up of a collection of particles with sizes ranging from 0.1 millimeters to more than 50 millimeters. It consists of aggregates such as gravel, crushed rock, sand, recycled concrete, and slag. When combined with a hydraulic cementing media, aggregate can be any granular material, such as sand, gravel, crushed stone, hydraulic-cement concrete, or iron blast-furnace slag, to create concrete or mortar. Due to their enhanced strength and economic advantages, aggregates are used in concrete in the construction sector.

Types of aggregate

There are two types of aggregates, such as coarse aggregate and fine aggregate. Each type's aggregate is further separated into numerous types and categorized according to size.

Coarse aggregate

Stone that has been split into small pieces and is shaped differently makes up coarse aggregate. Aggregates including limestone, granite, and river aggregate are used in construction projects. Aggregate with a size greater than 4.75 mm or retrained on a 4.75 mm IS Sieve is classified as coarse aggregate, and its maximum size is 63 mm.

Specifications For Good Quality Coarse Aggregate

The following critical factors should be taken into account by engineers when choosing high-quality coarse aggregates:

To withstand crushing, aggregate must be both strong and tough.

In order to maintain the bonding strength between concrete and aggregate, they should not be covered in organic materials, clay, or dust.

They shouldn't have a lot of angular, pointy, or hard particles in them.

The ideal aggregate shape should be either spherical or cubical.

Water absorption in aggregates shouldn't be greater than 5% of their actual weight.

The optimal size of coarse aggregates should pass through an IS 63 mm sieve and be retained on an IS 4.75 mm screen.

Uses of coarse aggregate

They are also utilized in the preparation of breaking moisture under slabs and vapor barriers.

They are also used in the base preparation for driveways and streets.

These aggregates are used to improve drainage in order to maintain perimeter drains, septic leach fields, and retaining walls.

Also used on temporary road surfaces (think gravel roads) and to create tire knock areas for trucks leaving building sites.

Fine aggregate

Fine aggregates are essentially any natural sand particles that are extracted from the earth through mining. Fine aggregates are any broken stone fragments that are 14" or smaller, such as natural sand. This product is frequently referred to as 1/4'" minus because it describes the size, or grading, of this specific aggregate.

Specification for good quality fine aggregate

The following critical factors should be taken into account by engineers when choosing high-quality fine aggregates:

Fine aggregate should be free of lumps, organic debris, and other impurities.

It must be sturdy and long-lasting.

After mixing, it shouldn't react with cement.

It should also have a sturdy floor.

It shouldn't soak up more water than 5% at a time.

These aggregates shouldn't be permeable or soft.

4.75 mm or smaller is the minimum size for fine aggregates.

Uses of fine aggregate in concrete mix

The structural filler that makes up the majority of the volume in concrete mix formulas is fine aggregate. The production can be significantly affected by the composition, shape, size, and other characteristics of fine aggregate.

Dimensional stability is added to the mixture by fine particles.

Adding fine aggregate to concrete can change its elastic modulus and abrasion resistance.

The grade of fine particles has an impact on the mixture's components and hardening characteristics as well.

Concrete shrinkage is significantly influenced by the characteristics of fine particles as well.

Applications For Aggregates In Construction

Different applications for coarse aggregates can be found in the construction sector. In road and railroad construction, aggregates are also utilized as ballast to resist the overall load, evenly distribute the load throughout the soil base, and drain off rainwater. The moisture and vapor barriers under the slab can alternatively be made of aggregate.They also have a significant impact on water filtration and sewage treatment procedures. swiftly from the road. Primarily, coarse aggregates are used to provide the base for roads and driveways.

The following three categories can be used to summarize aggregate uses:

As a material that infiltrates

As a material for bearings

Utilized as a filler

Aggregate Applications in Concrete

Concrete mixtures are made more compact with the aid of aggregate components,

60–65% of concrete's volume is acquired by aggregate.

It is utilized to give concrete a solid structure.

Concrete surface cracking and shrinkage are both decreased by aggregate.

In order to construct massive buildings, such as different building components, bridges, foundations, etc., coarse aggregate is employed in concrete.

Construction costs are reduced because surface area decreases with increasing coarse aggregate size and because less cement (the binding agent) is needed.

A combination of coarse and fine aggregate is used in concrete to increase its density, hardness, and resistance to atmospheric action.

They are essential for the construction and maintenance of rigid structures because they boost concrete's mechanical strength while using less cement and water.

Aggregate Uses in Road Construction

Aggregate are used in construction of road for various purpose:

In a variety of ways, aggregates are utilized in the construction of roadways for the surface, subsurface, and base.

In the process of stabilizing soil with cementitious materials, aggregate is used (blends of cement, fly ash, slag, lime).

Additionally, they are applied in the stabilization of bituminous materials (bitumen or tar).

Added more materials to stabilize (resins, fibers, geo-synthetics).

Aggregate is a material used in roads to help with load distribution and to guide rainwater runoff.

Properties of aggregate

Aggregates have a significant impact on the economy, mixture proportions, and qualities of freshly mixed and hardened concrete. Therefore, selecting aggregates is a crucial task. While there will be some variation in aggregate attributes, However, there are some aspects of aggregate that affect how the final concrete mix behaves. They are listed below.

Composition

Size and Shape

Surface Texture

Specific Gravity

Bulk Density

Voids

Porosity and Absorption

Bulking Sand

Modulus of Aggregate Fineness

Aggregate Surface Index

Deleterious Material

Aggregate Crushing Value

Aggregate Impact Value

Aggregate Abrasion Value

Composition

Use should never be made of aggregates made of substances that, when combined with the alkalies in cement, might cause excessive expansion, cracking, and other damage to the concrete mix. Therefore, testing aggregates is necessary to determine whether or not such constituents are present in the aggregate.

Size and shape

The quality of the concrete and the amount of cement required are significantly influenced by the size and form of the aggregate. It also affects the concrete's resilience and strength. A fine aggregate is an aggregate with a size less than 4.75 mm, whereas a coarse aggregate is one with a size greater than 4.75 mm. In reinforced concrete, aggregate size cannot be less than 20mm at its maximum.

Surface texture

The surface texture describes how smooth, polished, or rough the aggregate's surface is. The strongest bond forms when the surface is rough but porous. The setting of cement paste in the pores of porous surface aggregates causes an increase in bond strength.

Specific gravity

The weight of a given volume of aggregate divided by the weight of a corresponding volume of water is known as specific gravity. A temperature of 73.4°F (23°C) results in water with a specific gravity of 1. An aggregate's specific gravity is regarded as a gauge of the material's toughness or quality. Low specific gravity aggregates are often weaker than ones with a high specific gravity. This characteristic aids in the overall identification of aggregates.

Bulk Density

An aggregate's bulk density, also known as its unit weight, is the amount or weight of the material needed to fill a container with a given unit volume.

Bulk Density = Mass/volume

Aggregate bulk density is influenced by the following three elements.

Size of the compaction

aggregates grading

amorphousness of aggregate particles

Voids

The void areas between the aggregate particles of the compacted mix are known as voids in the mineral aggregate (VMA). The volume of void is equal to the difference between the aggregate mass's gross volume and the volume occupied by its individual particles.

Porosity and Absorption

By completely submerging the aggregates in water in the interstitial void area between them, the porosity of these packings is evaluated. The porosity is calculated by dividing the water's weight by its density and the volume of the pipe that contains the aggregates. The mass gain brought on by the presence of water in the material's pores is known as aggregate absorption. Porosity increases caused an increase in water absorption while decreasing compressive strength and impermeability.

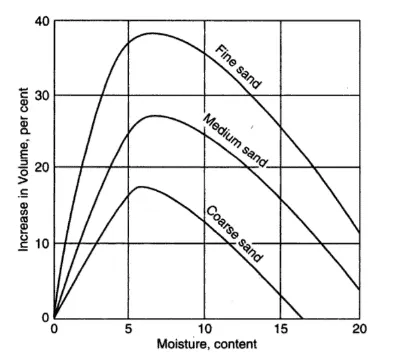

Bulking Sand

The phenomenon of a rise in sand volume brought on by an increase in moisture content is known as bulking of fine aggregate or sand. Fine aggregates must undergo a bulking test before being used in construction. Two factors affect how the aggregates are bulked:

The aggregates' degree of fineness

Proportion of moisture content

The above figure shows that the clumping of sand increases as moisture levels rise. Up until a certain point, any additional moisture causes the volume to decrease. There is no bulking in a thoroughly saturated fine aggregate. Inversely correlated with aggregate size is the bulking rate. As a result, fine aggregates bulk more than coarse aggregates.

Modulus of Aggregate Fineness

The fineness modulus (FM), which is used to help calculate proportions for concrete mix design, is a measure of the mean particle size of an aggregate sample.

The fineness modulus is typically used to determine the aggregate's coarseness or fineness. A higher fineness modulus value suggests a coarser aggregate, whereas a lower fineness modulus value indicates a finer aggregate.

The fineness or coarseness of the aggregate is normally assessed using the fineness modulus.

A coarse aggregate is suggested by a greater fineness modulus value, whilst a finer aggregate is suggested by a lower fineness modulus value.

Aggregate Surface Index

In comparison to coarse aggregate, fine aggregate has a larger surface area.Another factor used to grade the aggregate is the identification of the coarse aggregate's surface area. The specific area is only the aggregate surface area per unit rate.

Deleterious Material

Aggregates should not contain any toxic materials in sufficient quantities to compromise the strength and durability of the concrete. Such hazardous compounds are referred to as deleterious materials. Deleterious components are largely the same as those found in coarse aggregates composed of clay lumps, shale, soft, friable, or laminated particles, vegetative waste, or other unpleasant material.The following impacts may be caused by harmful compounds.

Silt, clay, and dust can coat aggregate particles, weakening the bond between the aggregate and the cement paste.

Excessive concentrations of these fine components may also raise the water demand of the concrete, resulting in concrete strength loss and permeability rise.

Aggregate Crushing Value

The Aggregate Crushing Value (ACV) Test Set determines how resistant an aggregate is when crushed under a gradually applied compressive stress. Each set includes a steel cylinder, plunger, base plate, cylindrical measure, and tamping rod.

Aggregate crushing value = (W2 x 100) / (W1-W)

W1-W =Weight of surface dry sample. The aggregate crushing value is the mean of two results rounded to the closest whole number.

This test's goal is

To determine the aggregate crushing value of coarse aggregate.

Examine the suitability of coarse aggregates for usage in various types of roads.

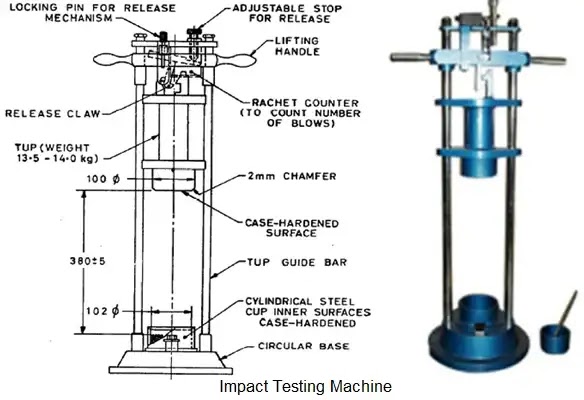

Aggregate Impact Value

The Aggregates Impact Value (AIV) Apparatus is used to calculate the aggregate impact value, which offers a relative assessment of an aggregate's resistance to rapid shock or impact.

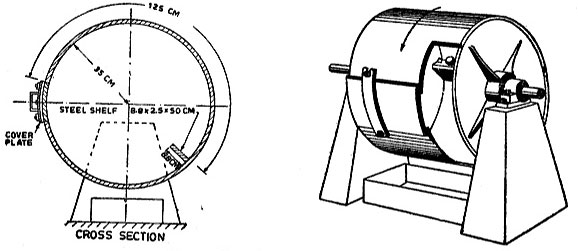

Aggregate Abrasion Value

When an aggregate is rotated in a cylinder with an abrasive charge, the abrasion value provides a relative measure of its resistance to wear.